Catastrophic’ Hurricane Helene makes landfall in Florida (France24)

Climate change destroyed an Alaska village. Its residents are starting over in a new town (AP News)

Deadly Thai floods intensified by climate change, La Niña displace 150,000 families (Voa News)

UN head warns of ‘a rising tide of misery’ as sea levels rise (Le Monde)

Climate change supercharged Europe floods – scientists (BBC)

Siberia to Brazil, Climate-Fueled Wildfires Move Underground (Bloomberg)

Roadmap For U.S.-India Initiative to Build Safe and Secure Global Clean Energy Supply Chains (The White House)

Amazon Joins Firms in $180 Million Brazil Carbon Credits Deal (Asia Financial)

“Decarbonization is the biggest transformation of the global economy of this century. But we risk entrenching a two-speed global transition”: Simon Stiell (UNFCCC)

Decarbonization and Electrification: A Roadmap to Federal Net-Zero (U.S. Department of Energy)

Investments in biofuels and green hydrogen on the rise: S&P Global (CNBC)

Why Investing in Climate Action Makes Good Economic Sense (Boston Consulting Group)

Aligning AI and climate governance (United Nations)

Colombia Looks to Future Without Oil in $40 Billion Transition Plan (Financial Post)

How investing in coal phase-out can lead to an $85 trillion opportunity (World Economic Forum)

Amazon expects to remain renewable energy’s top buyer (Axios)

US lawmakers plan bill to boost US maritime capabilities, citing global threats (S&P Global)

California Plan for Corporate Carbon Accounting Pushes Forward (The Wall Street Journal)

Global efforts to drastically reduce greenhouse gas (GHG) emissions by 2050 are intensifying. The Paris Agreement aims to limit global temperature rise to below 2°C, preferably 1.5°C. Achieving the Paris goals requires reaching net-zero emissions in the latter half of the century, with near-zero emissions necessary by 2050 to limit warming to 1.5°C.

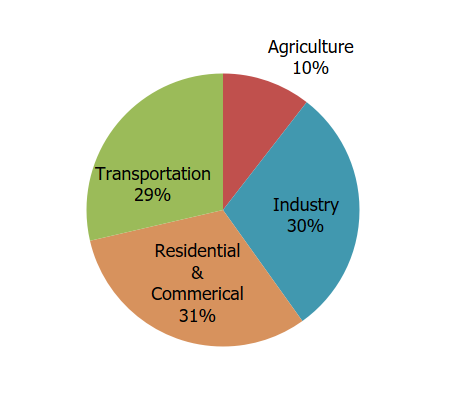

In 2022, the industrial sector was responsible for approximately one-third of global energy consumption and one-quarter of CO₂ emissions (about 9.0 GtCO₂). In the United States, the industrial sector accounted for 33% of the nation’s primary energy use and 30% of its energy-related GHG emissions, making decarbonizing industry crucial to addressing the climate crisis and achieving carbon neutrality.

Industry emissions come not only from energy use but also from processes like the production of F-gases (fluorinated gases used in industrial applications).

Decarbonizing industry is particularly challenging for sectors where it is difficult to substitute raw materials in manufacturing. However, various strategies have been developed to tackle these barriers. Key decarbonization measures include energy and resource efficiency, fuel and material switching, process optimization, heat recovery, electrification, recycling, carbon capture, and the use of renewable energy and bio-based materials.

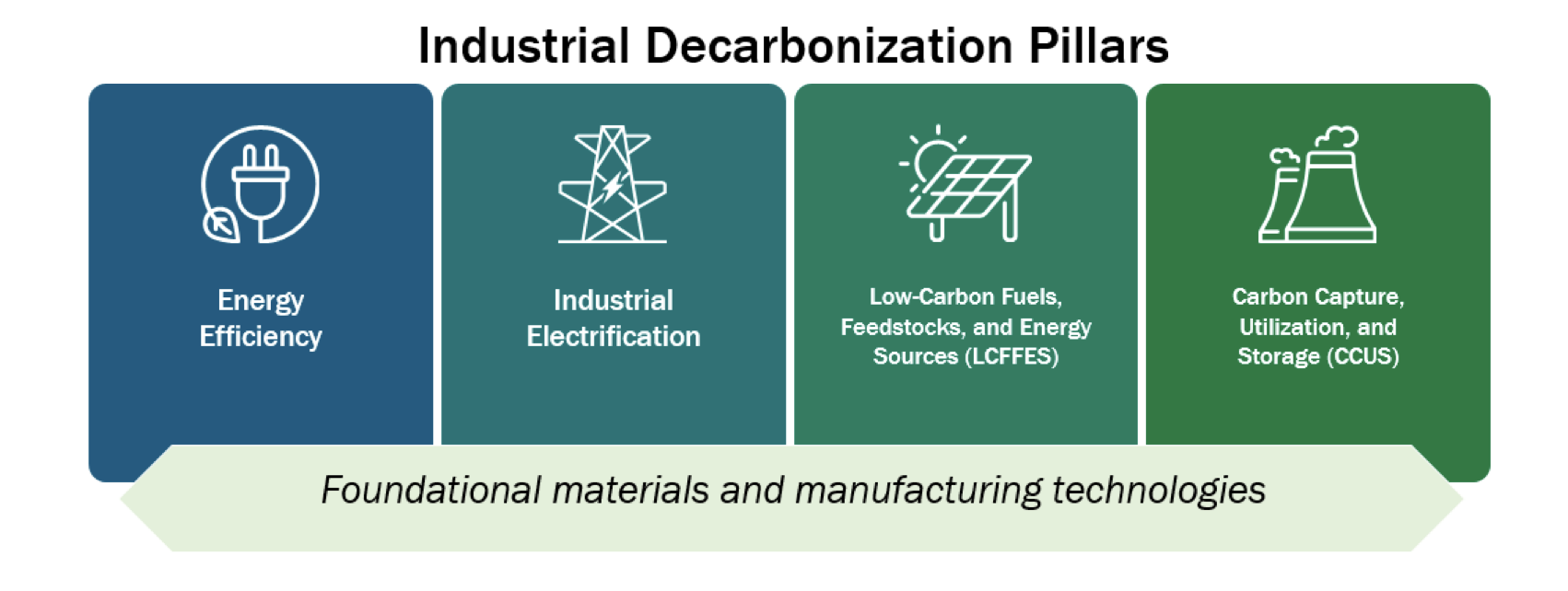

The U.S. Department of Energy (DOE) categorizes these strategies into four pillars: energy efficiency, electrification, low-carbon resources, and carbon capture, utilization, and storage (CCUS). These approaches are essential for reducing industrial greenhouse gas emissions.

The industrial sector is foreseeing the adoption of emerging technologies like electrification and CCUS to meet zero emissions by 2050. In the near term, energy efficiency remains the most effective and immediate strategy, while transformative technologies will bring long-term reductions.

The DOE’s Better Plants Program supports over 270 manufacturers in adopting energy-efficient practices, improving competitiveness, and reducing emissions. Globally, other nations are following similar paths. The UK, EU, and Australia have outlined energy efficiency and decarbonization roadmaps, targeting significant reductions in energy use and emissions by 2050, with sector-specific solutions deployed based on industrial needs.

Integrating and adopting advanced manufacturing technologies and circular economy principles is a powerful approach to significantly reducing greenhouse gas (GHG) emissions across various industries while creating more sustainable, resilient production systems.

These technologies enable more efficient resource use, energy reduction, and the adoption of sustainable practices that are crucial for meeting global decarbonization goals.

As technologies like 3D printing, AI, and intelligent factories continue to evolve, industries have the opportunity to significantly reduce waste, lower emissions, and create products that last longer and use fewer resources.

Here are some examples of how they can interact:

1. Energy Efficiency and Optimization:

Example: Siemens’ smart factory technologies have reduced energy use in manufacturing operations by optimizing equipment performance and reducing idle time.

2. Reducing Embodied Carbon in Products:

Circularity and advanced manufacturing technologies help reduce the embodied carbon in products—the carbon emitted during production, transportation, and disposal.

Example: Patagonia uses recycled materials in its outdoor apparel and designs its products for durability and repairability, reducing the carbon emissions associated with manufacturing new products.

3. Circular Economy and Resource Efficiency:

Example: Caterpillar’s remanufacturing program, which uses robotics to refurbish old equipment and components, significantly reduces the energy and emissions involved in producing new equipment.

4. Decarbonizing Industrial Processes with AI and Digital Twins:

Advanced digital technologies such as AI and digital twins help industries optimize processes and reduce emissions by providing data-driven insights.

Example: The Port of Rotterdam uses a digital twin to optimize logistics and port operations, reducing fuel consumption and emissions from ships and transport vehicles.

5. Additive Manufacturing (3D Printing):

Example: GE Aviation’s 3D-printed fuel nozzles for jet engines are lighter and more efficient, reducing fuel consumption and emissions during flights.

6. Electrification and Renewable Energy Integration:

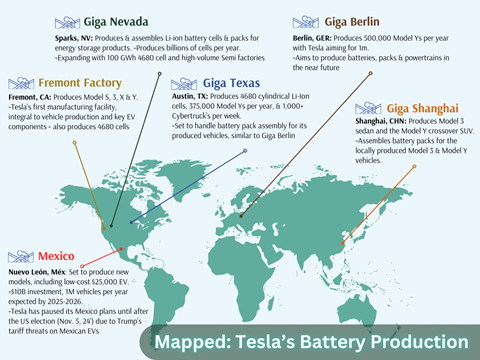

Example: Tesla’s Gigafactories produce electric vehicle batteries using advanced manufacturing processes. They are powered by renewable energy sources and designed to minimize emissions throughout production.

7. Supply Chain Decarbonization:

Example: Adidas uses 3D printing and localized production to reduce supply chain emissions. This allows them to produce shoes closer to consumer markets, lowering the carbon footprint associated with long-distance transportation.

8. Reduction of Industrial Emissions:

Example: ArcelorMittal, one of the world’s largest steel producers, uses AI-based technologies to optimize its steel production processes, reducing the amount of energy required and cutting down on associated emissions.

9. Product Lifecycle Extension:

Example: Rolls-Royce uses predictive maintenance powered by AI to keep its jet engines in service longer, reducing the need for new parts and cutting down on emissions related to manufacturing new engines.

10. Sustainable Material Use:

Example: The development of composite materials in the automotive and aerospace industries, which are lighter than traditional metals and reduce fuel consumption, lowering emissions over a product’s lifecycle.

Challenges:

Opportunities:

Advanced manufacturing and circularity play a critical role in the transition toward decarbonization by enabling more efficient, flexible, and sustainable production systems. From energy efficiency and resource optimization to integrating renewable energy and reducing supply chain emissions, advanced technologies and circular economy principles are paving the way for industries to significantly reduce their carbon footprint. As manufacturing continues to evolve with the adoption of technologies like AI, robotics, and additive manufacturing, the potential for further decarbonization grows, helping industries meet global climate targets and move toward a more sustainable future.

Beatriz Canamary is a consultant in Sustainable and Resilient Business, Doctor and Professor in Business, Civil Engineer, specialized in Mergers and Acquisitions from the Harvard Business School, and mom of triplets. Today she is dedicated to the effective application of the UN Sustainable Development Goals in Multinationals.

She is an ESG enthusiast and makes it possible to carry out sustainable projects, such as energy transition and net-zero carbon emissions. She has +15 years of expertise in large infrastructure projects.

Member of the World Economic Forum, Academy of International Business and Academy of Economics and Finance.